Nokubaiiglasi zokujikeleza or imicu yeglasi emfutshane, i-fiberglass ephambili or precio fibra de carbonozongezwa kwi-matrix ye-thermoplastic, injongo ngokusisiseko kukuphucula izixhobo zomatshini kunye nezakhiwo zepolymer.Kukho iiyantlukwano ezininzi phakathi kweendlela ezimbini eziphambili zokuqinisa i-thermoplastics yokubumba inaliti, ukusuka kwindlela edityaniswe ngayo kunye ne-polymer matrix, ukuya kwinqanaba lokusebenza abanokubonelela ngayo, kwaye enye ifom yefayibha inokuba ngaphezulu Enye ifanelekile ngakumbi, kodwa umehluko, umahluko ophambili phakathi kwemicu emifutshane kunye nemide yinqanaba ekusetyenzwa ngalo.

Ukusetyenzwa kwefiber ende eyomeleziweyo kwi-thermoplastics

Eyona njongo iphambili yokusetyenzwa kwe-thermoplastics eyomelezwe ngefayibha ende kukugcina ubude befiber, obubaluleke kakhulu ekwandiseni amandla kunye nokuqina.Ukuqhekeka kwefayibha kunokuba nefuthe elibi kwiipropati ze-polymer composite kwaye ekugqibeleni zingayigatya izibonelelo zokusebenzisa imicu yefiber yeglasi.Ukuphathwa ngendlela engafanelekanga kunye nezixhobo eziphosakeleyo kunye noyilo lwamacandelo, okanye ukusetyenziswa kwezixhobo zokucwangcisa ezingalungiswanga okanye ukusetha, kunokukhokelela ekuqhekekeni kwefayibha.

Ngokungafaniyo neeplastiki eziqiniweyo zefiber ezinqunqiweyo, izinto eziqinisiweyo ezinde zefiber zihlala zenziwe yi-pultrusion.Inkqubo ibandakanya ukolulaiglasis ukuzulazulaukufakwa ngentlaka ye-thermoplastic ngokufa okukhethekileyo (ukuze i-resin ikwazi ukujikeleza kwaye ibophe iintsinga), kwaye emva koko usike imisonto ekhutshiweyo kwiipellets, imicu kwiipellets iqhele ukuba yi-12mm Iimpawu ezide, ezigcweleyo ezigcweleyo zokuqinisa ifayibha enye. , kwaye obu bude bubalulekile ukwenzela ukuba i-polymer idlulise ngokufanelekileyo uxinzelelo kwiintsinga ezinamandla.

Xa ezi pellets zisetyenziselwa ukubumba inaliti, imicu emide ilungelelaniswa kwaye inxeba eliqinileyo ukwenza i-skeleton yangaphakathi enika amandla kunye nokuqina.Xa kuthelekiswa nezinto ezizaliswe yifayibha emfutshane, imidibaniso eyomelezwe ngemicu emide, nokubaiifiberglass fibersokanye iifibers zekhabhoni, zibonelela ngamandla-to-weight ratios, ukuqina kwempembelelo, ubomi obude bokudinwa komjikelo, kunye nokumelana nobushushu okubanzi kunye nokuzinza okungcono komgangatho.

Ezi mathiriyeli zihlala ixesha elide zibonelela ngolwakhiwo olunokuthelekiswa nentsimbi, kodwa zikhaphukhaphu kunentsimbi, kwaye ziyakwazi ukuthatha ithuba leenzuzo zokusetyenzwa kakuhle kwenaliti yokubumba.1k ilaphu le-carbon fiberzixabiseke kakhulu njengokutshintshwa kwentsimbi kuba zikhaphukhaphu ngama-70% kunentsimbi kwaye zikhaphukhaphu kunentsimbi.I-aluminiyam i-40% ikhaphukhaphu, ngoko ke imihlanganisela eyomelezwe ixesha elide ingasetyenziselwa ukwenza amacandelo anzima kwiimoto, kwimpahla yezemidlalo, kwi-aerospace, iimpahla zabathengi kunye nezixhobo zoshishino.I-resin ezisisiseko eziqhelekileyo ziquka i-polyamide (i-PA okanye i-nylon), i-polypropylene (PP), i-thermoplastic polyurethane (ETPU), kunye ne-resin ephezulu yokushisa njenge-polyetheretherketone (PEEK), i-polyphthalamide (PPA), kunye ne-polyamide.I-Ether imide (PEI) njl. Nangona nayiphi na i-thermoplastic inokuqiniswa ngeefibers, kuphela ezinye zinika ukusebenza okuphezulu ngenxa yokuba zomelezwe ngcono.Ngokuchanekileyo, i-semi-crystalline resins iqiniswe ngcono yi-fibers kune-amorphous resins, oku kuthetha ukuba ukuqina kunye namandla abo anyuka ngakumbi.

Amanqaku oLungiselelo lweZizinto eziQinisekisiweyo zeFiber ende

Xa kuthelekiswa ne-resins engalungiswanga okanye i-granular powder-ezaliswe yi-resins, ukubumba i-fiber ende eqiniweyo i-composites ineemfuno ezithile zokubumba, amasango, izixhobo zokubumba, kunye noyilo lwenxalenye.Iinkqubo ezisetyenziselwa ukucubungula ezi mathiriyeli zikwahluka kwezo zepolymers ezifayibha ezimfutshane.

Njengoko bekutshiwo ngaphambili, ukugcina ubude befayibha sisitshixo sempumelelo.Izinto ezinokubangela ukufinyezwa kobude befayibha ziquka uxinzelelo oluphezulu kunye nokucheba ukusuka kwisikrufu sokutofa, njengoko kunokubakho iikona ezibukhali kwisixokelelwano sokungunda kunye nembaleki.Ukugcina ubude befayibha, kukho iingongoma ezi-3 eziphambili ekufuneka uziqaphele:

1. Izinto zokubumba kunye noyilo

Nangona iintambo ezinde zinxiba ngaphantsi kokungunda kunemicu emifutshane ngenxa yokuba kukho iziphelo ezimbalwa ezifana nenaliti ezichaphazela umngundo, uhlobo olufanayo lwentsimbi yokubumba lufanelekile kuzo zombini iipolymers eziqinisiweyo ende kunye nefiber emfutshane, eyona ixhaphake kakhulu. yintsimbi yokubumba i-P20, enokumelana nangaphezu kwe-100,000 yokutofa ngokuqhubekayo.Ukuba ukuqina okuphezulu kuyafuneka (ngaphezu kwe-100,000 imijikelezo yokutofa), i-H13 chrome molybdenum steel okanye i-A9 air hardened steel zikhetho ezingcono.Ngokubanzi, ukubumba okuqinileyo lolona khetho lulungileyo lokulungisa i-fiber-reinforced thermoplastics.Kwizibungu ezigugileyo, zinokuhlaziywa ngokusebenzisa iteknoloji ye-electroplating.Imibumbo yeAluminiyam ingade isetyenziswe ukuba iiprototypes kufuneka ziveliswe ukuze kuqinisekiswe uyilo.

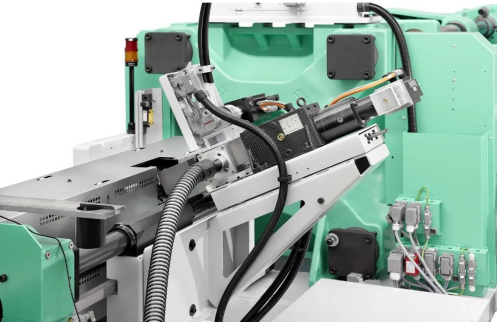

2. Ukwenza izixhobo

Ifayibha ende eyomeleziweyo ye-thermoplastics inokucutshungulwa kusetyenziswa isixhobo sokubumba isitofu esisemgangathweni kunye nohlengahlengiso olungephi olusisigxina ukugcina ubude befayibha kunye nokwamkela i-viscosities ephezulu.Uxinzelelo oluphantsi okanye i-screw yenjongo ngokubanzi kunye neringi engabuyiyo evumela ukuhamba ngokukhululekileyo phezulu kuyacetyiswa.Imilomo yenjongo gabalala ingasetyenziswa, kodwa imilomo yenayiloni kufuneka iphetshwe kuba imilo yayo yehourglass (eyenzelwe ukuthintela ukuthontsiza) inqanda ukuhamba, idale ukucheba, kwaye ibangele ukukrazuka kwefiber.Elinye icebiso lokunciphisa ukucheba kukunqanda uyilo olujijekileyo lombhobho wecone.Ngokuqhelekileyo, imingxuma emikhulu ye-nozzle (ubuncinci be-5.6 mm) iququzelele ukuhamba kwe-viscous fiber-reinforced resins.

Umgaqo olungileyo wobhontsi wawo nawuphi na umatshini wokutofa kukutofa kuphela i-60-70% yomthamo.Ubungakanani bokudutyulwa okuninzi konyusa ixesha lokusetha ngokutsha, ngelixa ubungakanani bokudubula obuncinci buthetha ukuba izinto zihlala emgqomeni ixesha elide, okunokukhokelela ekuthotyweni.

3. Iimeko zokucubungula

Ngokubhekiselele ekuqhubekeni phambili, kubalulekile ukujongana nemiba emibini: i-warpage kunye ne-creep.Ngokubanzi, ifayibha ende eyomeleziweyo amalungu e-thermoplastic amava angaphantsi kwe-warpageI-fiberglass ene-strand emfutshaneAmalungu ngenxa yokuba ukujija kwefilament kunciphisa ukushwabana okwahlukileyo, kodwa inaliti ebumba iindawo zefiber ezinde zisakhubazeka, esinye isizathu kukuba iintsinga zihamba ecaleni kolungelelwaniso lwe-Orientation, ngelixa ukhulisa amandla enxalenye, kunokukhokelela kwi-anisotropy.Ukuthintela ukulwa, ezinye iindawo zesango okanye iinxalenye zoyilo zingasetyenziselwa ukuphepha ukulungelelaniswa kwefayibha ngokugqithiseleyo kwiindawo ezingadingi amandla aphezulu okumelana nemithwalo yesakhiwo.

Gcina i-advanteji yemicu emide

Ukuphumelela ukubunjwa kwee-composites ze-fiber ezide eziqiniweyo kufuna ukuguqulwa kwezikhokelo zoyilo kunye neeparitha zokucubungula ezisebenzayo kwi-resin engaqiniswanga kunye ne-fiber compounds emfutshane.Ukufumana okuninzi kwiifayibha ezide zokuqinisa (ezixabisa ngaphezulu kwemathiriyeli engazaliswanga okanyei-fiberglass enqunqwe imisonto yokuqinisangenxa yokusebenza kwawo okuphezulu), ezona ndlela zingcono kufuneka zilandelwe kuyo yonke le nkqubo.Ukuba iintsinga ezinde zophukile okanye azilungelelaniswanga ngenxa yokuphathwa kakubi, uyilo lokufa okanye ukusetwa kwezixhobo, amandla abo aphezulu kunye nokuqina okuphezulu kuya kuncipha okanye kulahleke.

#iiglasi zokujikeleza#imicu yeglasi emfutshane#1k ilaphu le-carbon fiber#I-fiberglass ene-strand emfutshane#i-fiberglass enqunqwe imisonto yokuqinisa

Ixesha lokuposa: Oct-21-2022